Our Resource LIBRARY

As you embark on your own journey to becoming experts in Lean Six Sigma, you will learn that the concepts of Lean Six Sigma are applicable in any process across any industry, as well as applicable in your personal life.

We have created a wide variety of valuable resources for our Variance Reduction community. These resources are available free of charge, we would however like to request that when used their reference is made to the source.

Welcome to our Community!

Knowledge through Sharing

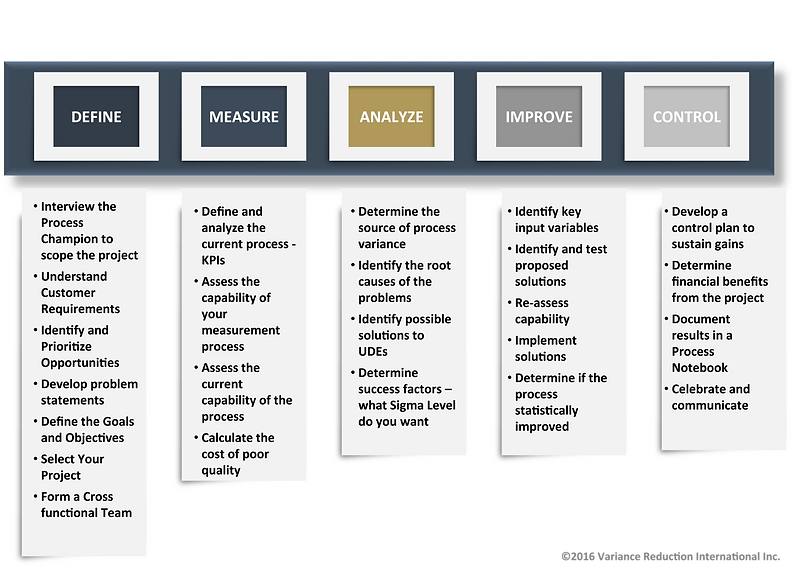

Stepping Through DMAIC with VRI

DMAIC is a data-driven, structured, customer-centric problem solving methodology. Each phase builds on the last to arrive at effective solutions for challenging problems. It involves using the right tools at the right time to answer the right questions. The Lean Six Sigma Methodology comprises of five phases:

Stepping thru DMAIC

Define

The Define in the DMAIC process is about selecting high-payback projects and identifying the underlying metric(s) that will measure project success. Without senior leadership oversight and support, project leaders will typically be overwhelmed with resistance from the organization, and will make little progress. Outlined below are is a brief overview of the most common tools used in this phase. The key deliverable of the define stage is an agreed project charter.

Define Phase Objectives

-

Interview the Process Champion to scope the project

-

Understand Customer Requirements

-

Identify and Prioritize Opportunities

-

Develop Problem Statements

-

Define the Goals and Objectives

-

Select Your Project

-

Form a Cross Functional Team

The Measure in DMAIC is about understanding the current process, how the process is measured, and its baseline (historical or pre-Lean Six Sigma) performance. Outlined below are is a brief overview of the most common tools used in this phase.

Measure Phase Objectives

-

Define and analyze the current process – KPIs

-

Assess the capability of your measurement process

-

Assess the current capability of the process

-

Calculate the cost of poor quality

Stepping thru DMAIC

Measure

Stepping thru DMAIC

Control

Control Phase of the Lean Six Sigma DMAIC Process consists of executing the Control Plan and finalizing the project documentation. Monitor post implementation process performance to ensure expected improvement in the project has occurred. Ensure ongoing process monitoring system is in place. Communicate the Business Results and sign off to close the Lean Six Sigma Project. Outlined below are is a brief overview of the most common tools used in this phase.

Control Phase Objectives

-

Develop a control plan to sustain gains

-

Determine financial benefits from the project

-

Document results in a final report

-

Celebrate and communicate

Stepping thru DMAIC

Analyze

This phase starts with team input regarding potential causes and uses statistical methods to isolate the top issues to be discussed. Oftentimes there is one primary cause that is driving most of the unwanted variation, and controlling or eliminating this cause is all that is needed. Outlined below are is a brief overview of the most common tools used in this phase.

Analyze Phase Objectives

-

Determine the source of process variance

-

Identify the root causes of the problems

-

Identify possible solutions to UDEs (Undesirable Effect)

-

Determine success factors – what Sigma Level do you want

The Improve phase is about redesigning the process to achieve improved capability. This involves brainstorming potential solutions, selection solutions to test and evaluating the results of the implemented solutions. Outlined below are is a brief overview of the most common tools used in this phase.

IMPROVE Phase Objectives

-

Identify key input variables

-

Identify and test proposed solutions

-

Re-assess capability

-

Implement solutions

-

Determine if the process statistically improved